Case Studies

Water Testing Helps Commercial Property Manager Renew Lease

It is essential for businesses to provide safe drinking water for employees and visitors. This requires water testing.

In the summer of 2024, a property management company with a 125,000-square-foot warehouse in Southwest Ohio sought a qualified third-party to ensure their office space met local and federal guidelines for safe drinking water.

After several unsuccessful attempts to contract water service companies around the Greater Cincinnati area, Integrated Water Process (IWP) was engaged to perform the required water sample collection, water testing and analysis to satisfy the terms of the company’s lease agreement.

Why Integrated Water Process for Water Testing and Analysis?

- Qualified: IWP is an Ohio-licensed engineering firm specializing in large-scale commercial water management. The company’s founder and principal, Brad Hull, PE, was chosen to conduct these services because credentials and experience surpasses the required Public Building Service (PBS)’s standards.

- Third-Party: By bringing on a third-party company like IWP for this work, methods and test results were guaranteed to be thorough and unbiased to ensure safety measures and standards were met.

- Superior Service: Superior Service: From the first call, IWP quickly developed a customized water service proposal with clear deliverables, a completion timeline, and fixed pricing. The proposal also outlined any additional services that might be needed after the initial testing, giving the building management flexibility to address potential contamination swiftly.

- Integrated Offering, this allowed for Hull to be the single point of contact during the three-month long engagement.

Investigative Work Prior to Water Testing and Analysis

IWP first visited the site to observe the water system and take inventory of all the water outlets in the building. Although a building floor plan was available, the Mechanical, Electrical, and Plumbing (MEP) drawings were not found on-site, nor were they provided by the building owner or manager. This added to the challenge since much of the piping was either underground or within the office walls. In such situations, an experienced professional is needed to be able to quickly assess the as-built conditions and document them efficiently.

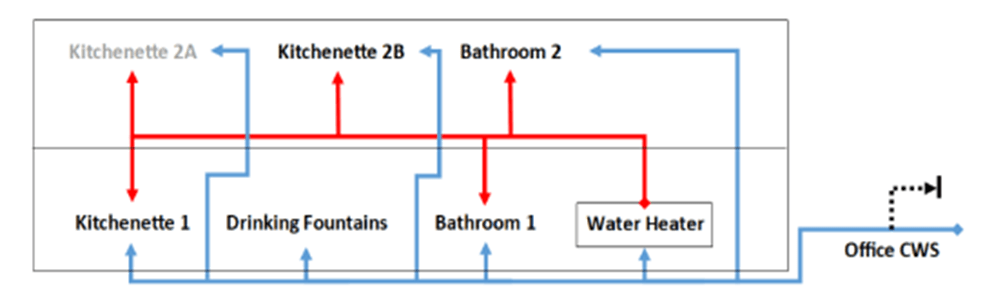

Figure 1: Simplified schematic drawing of the Cold-Water Supply (CWS) and the Hot Water Supply (HWS) supplying the consumption sites within the building.

To simplify the understanding of the existing water system, a basic diagram was created to show the Cold-Water Supply (CWS) and Hot Water Supply (HWS) to the building’s outlets. During this investigation, IWP identified all point-of-use outlets where water was expected to be consumed. The findings revealed low residual chlorine levels in some unused piping branches. This preliminary finding indicated a heightened risk of microbial contamination. Additionally, a damaged gate valve was identified on the incoming water service.

Water Sample Collection and Testing

The water testing and analysis focused on point-of-use outlets across all common areas, adhering to Ohio Administrative Code, Ohio Environmental Protection Agency (EPA) standard methods, and ISO quality standards. During the assessment, Hull conducted a thorough process, beginning with sample collection. First-draw samples were taken after flushing the outlets to ensure accurate readings. The primary targets for the analysis included Lead and Copper levels exceeding standard action limits, Total Coliform and E. coli levels above Ohio EPA standards, and any presence of Legionella. The results showed that Lead and Copper levels were below the necessary thresholds, but elevated Coliform and Legionella levels were identified in specific areas that required remediation.

Remediation and Future Risk Management

IWP developed a remediation plan for each affected area using Hazard Analysis and Critical Control Points (HACCP) principles. The first step was to drain and flush the impacted water systems. IWP also recommended demolishing unnecessary water outlets while preserving both the hot (HWS) and cold (CWS) water supplies. Additionally, IWP suggested installing accessible valves that would allow for regular flushing and flow, as required by the water management plan created for this site.

Throughout the process, IWP maintained a detailed daily log, identifying unsafe areas and retesting each point-of-use outlet to ensure the water was clean and safe for office use. IWP also created a long-term Risk Management Strategy for the company to help maintain water quality across the facility. By following this maintenance plan, the company can ensure safe drinking water throughout their leased office space, in accordance with Ohio regulations and standards.

Comprehensive Water Management Solutions

Integrated Water Process (IWP) quickly delivered services that successfully addressed water-related challenges. Hull served as the single point of contact, ensuring seamless communication and convenience for both the building management team and the tenant.

IWP provided:

- A Technical Service Proposal tailored to the property manager’s unique needs.

- Water Sample Collection for testing lead, copper, coliform, and Legionella.

- Analysis and Reporting as an unbiased third-party.

- Remediation of contamination, followed by appropriate testing to confirm success.

To ensure the safety and quality of your building’s water system, it’s crucial to have a comprehensive water management plan in place. Contact Integrated Water Process today to schedule a consultation and learn how our customized solutions can simplify your water management. Don’t wait—take proactive steps now to safeguard your facility’s water system. Let our experts guide you every step of the way!

Please stay tuned for more company news, technical articles, and other informative content designed to help simplify your water management!