Hydroponic Grow System Planning

Planning your Commercial Hydroponic Grow System

A large-scale, hydroponic grow system can help you achieve economies of scale in your controlled environment agriculture (CEA) business, but careful planning is critical to ensure success. Our in-house industry experts take a holistic approach to planning your commercial hydroponic grow systems to fully optimize your horticulture or produce greenhouse, or cannabis indoor grow water processes on a large scale. With over 12 years of experience building greenhouse irrigation systems, we know that planning an efficient hydroponics system requires a thorough understanding of how your irrigation systems work, their usage rates, and the various factors affecting water quality and availability. By developing a comprehensive approach, we’ll help you significantly improve water efficiency, reduce costs, and promote sustainable water management practices.

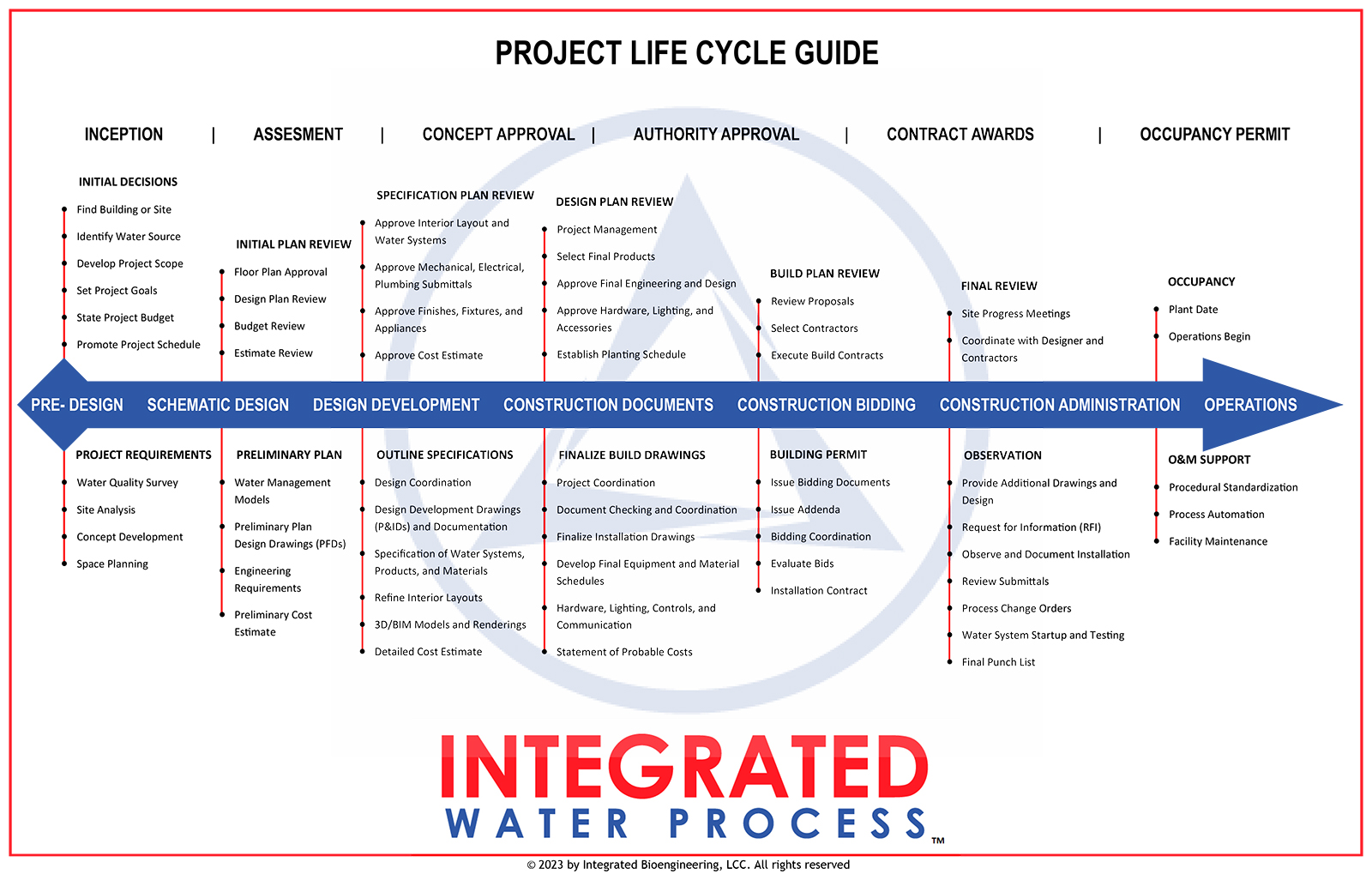

We work with you from the inception of your idea through the operation of your unique water system or infrastructure. The figure above is developed to help guide our clients in understanding Where They Are are in the development cycle and How Integrated Water Process Can Help. The figure below outlines the project development process as a series of steps from left to right along a blue arrow, including pre-design, schematic design, design development, construction documents, construction bidding, construction administration, and operations.

Below and above each developmental phase are tasks typically associated with that phase. The tasks listed above each phase are typically reserved for the owner or their management team. Below each phase are tasks that we can perform to simplify water management for greenhouse and indoor cultivation facilities.

The Planning Process

1. Water Management Planning Our team of experts will begin with a comprehensive consultation session to understand your goals, budget, and space requirements. This personalized approach ensures that you receive a tailored solution that meets your specific needs.

- Inception (starting point)

- Site Analysis

- Water Quality Analysis

- Resource Management Plan

- Compliance and Regulations

- Concept Development

- Space Planning

2. Hydroponic Schematic Design Steps Our specialists design and draft a system that optimizes space, efficiency, and yield for your specific crop selection.

- Preliminary Plan Design Drawings

- Model Water Management

- Provide Engineering Requirements

- Preliminary Cost Estimate

3. Hydroponic System Design Development Steps

- Design Coordination

- Design Development Drawings (PFD’s, P&IDS) and Documentation

- Specify Water Systems, Products, and Materials.

- Refine Interior Layouts

- 3D Models and Renderings (If Required)

- Detailed Cost Estimate

4. Hydroponic Construction Documents Steps

- Document Checking and Coordination

- Final Installation Drawings

- Final Equipment and Material Schedules

- Hardware, Controls, and Communications

- Statement of Probable Costs

5. Construction Bidding

- Issue bidding documents

- Issue Addenda

- Bidding Coordination

- Evaluate Bids

- Installation Contract

6. Construction Administration

- Provide Additional Drawing and Design

- Request for Information (RFI)s

- Observe and Document Installation

- Review Submittals

- Process Change Orders

- Water Startup and Testing

- Final Punch List

7. Operations and Maintenance

- Procedural Standardization

- Process Automation

- Facility Maintenance

- Training and Support

Ready to grow? Let’s talk about how we can help you plan and build your commercial hydroponic grow system.

Speak directly with one of our in-house experts and we’ll help you turn your plans into reality. Book a free consultation by clicking the button below to schedule an appointment.

What is the definition of a large commercial hydroponic grow system?

A large-scale, commercial hydroponic indoor grow system is an advanced method of cultivating plants without soil, using mineral nutrient solutions in a water solvent. This means that when you’re planning your hydroponics system, taking into consideration all the various factors that play into your water management is critical to its overall success.

Hydroponic grow systems allow for precise control over nutrients, light, and temperature, optimizing plant growth and yield. Ideal for controlled environment agriculture (CEA), including produce and horticultural greenhouses and cannabis indoor growing environments, these systems range from basic setups to complex, fully automated spaces for large-scale production in various climates and environments.

How do commercial-sized hydroponic grow systems work?

When planning a large, commercial-sized hydroponic grow system, it’s essential to have a high-level understanding of how they work and all the factors that need to be taken into consideration:

Hydroponic System Design

Commercial hydroponic systems are designed for large-scale production, often encompassing extensive produce or horticulture greenhouses, or high-output cannabis indoor grow facilities.

Before you can begin the design and drafting phase, it’s important to know the type/s of hydroponic systems you intend to deploy, including Drip, Nutrient Film Technique (NFT), Deep Water Culture (DWC), Aeroponics, and Ebb and Flow. Each type has its specific setup, advantages, and suitability for different plants and operations. Ultimately, we design your grow system to deliver what the plants AND your organization needs to be profitable.

Growing Medium

Unlike traditional farming, hydroponics primarily uses inert growing mediums like mineral wool or “rockwool”, coco coir, peat moss, perlite, dried clay, rice hulls, sand, gravel, or some combination. These varied growing mediums support the root structure and aid in oxygen and nutrient absorption. Plants are usually placed in uniform pots or grown in trays, ensuring they receive equal access to nutrient solution and climate conditions.

Hydroponic Method

A water-based solution containing essential nutrients like nitrogen, potassium, and phosphorus is tailored to the specific needs of the plants being grown. The nutrient solution can be delivered to the plants’ roots using various commercial methods, depending on the type of hydroponic system. Some plants and related systems submerge roots in a nutrient solution continuously, while others use a timed flooding and draining method. These variables depend on the plants’ needs and its phase of life.

Water Quality for Hydroponics

There are many benefits to water quality because it directly influences crop health and productivity. High-quality water ensures optimal nutrient delivery to plants, prevents soil salinity, and reduces the risk of diseases. Clean water supports efficient irrigation, promoting better absorption of essential elements and fostering robust plant growth. Ultimately, maintaining water quality enhances agricultural yield and improves crop quality.

Water Storage for Hydroponics

In hydroponics, correct water storage is vital for optimal plant growth. The water volume must be sufficient to maintain stable nutrient concentrations, and tanks, typically made of durable materials like plastic or coated metal, should be chosen wisely. The number and location of tanks depend on the system scale and plant types.

Easy service access is crucial for maintenance, with proper drainage preventing waterlogging. Pre-treatment methods such as filtration to ensure water quality are essential. Fill control systems to maintain consistent tank levels are also important.

Overall, a well-designed water storage system supports efficient nutrient delivery, prevents contamination, and enhances the longevity of the hydroponic system.

Nutrient Mixing (Fertigation)

Regular monitoring of pH levels and nutrient concentrations is essential for peace of mind. Your fertigation system is the heart of your water management strategy. Adjustments are automatically made to ensure the nutrient solution remains optimal for plant health. Commercial hydroponic systems can be designed precisely to conserve inputs and intelligently by recirculating the nutrient solution.

Water Delivery

Water delivery is essentially irrigation; water is delivered precisely to meet the demand of the specific crop. This can be performed simply with timers or for more control, you may want substrate monitoring devices and precision automated irrigation.

Automation and Technology Integration

Commercial hydroponics often integrates automation for nutrient delivery, for more precise and efficient operation. Some systems use IoT (Internet of Things) technology and data analytics to monitor plant health, predict yields, and optimize growing conditions to minimize manual labor.

What type of hydroponic system will suit your large-scale greenhouse or indoor grow facility?

Deciding on what kind of hydroponic system you’ll need for your greenhouse or indoor facility is critical to ensure the success of your operation. Our in-house experts will walk you through the pros and cons of the most common types of systems:

Drip Hydroponics

Drip hydroponics is a type of hydroponics that uses fluid emitters to create a drip irrigation system to top-feed nutrient solution onto the substrate of each plant. It is suitable for greenhouses and can be configured to be either recovery or non-recovery.

Aeroponics

Aeroponics is a method of growing plants in the air with their roots suspended in a nutrient mist. It uses less water than traditional farming methods and can grow plants faster due to the roots’ exposure to elevated oxygen levels. It is also a year-round method of growing plants and can be used for any plant except those with larger and heavier root systems.

Dutch Buckets

Dutch Buckets is an active recovery system that uses a pump to send nutrient water up irrigation lines and into growing media within buckets of potted plants. The excess water is drained back into a reservoir.

Ebb & Flow (AKA Flood & Drain)

Ebb and Flow hydroponics is a technique for growing plants in a controlled environment. Plants are placed on grow beds filled with growing medium, above a reservoir that periodically floods the grow bed with nutrient solution. This system has a timer and an overflow tube to prevent over-flooding. The roots dry out between floods, which helps to oxygenate them.

Deep Water Culture (DWC)

Deep Water Culture (DWC) is a hydroponic method that suspends the roots of plants in aerated nutrient solution with a grow medium holding the plants above the nutrient solution, which is contained in a deep reservoir. A circulation pump connected to an airstone ensures that the roots receive enough oxygen. This type of hydroponic system is ideal for growing large plants with extensive root systems or abundant fruit, such as pepper plants.

Frequently Asked Questions:

Ready to grow? Let’s talk about how we can help you plan and build your commercial hydroponic system.

Speak directly with one of our in-house experts and we’ll help you turn your plans into reality. Book a free consultation by clicking the button below to schedule an appointment.