ARTICLES

Indoor Growers Benefit from Understanding Filtration

MECHANICAL FILTRATION DEFINED

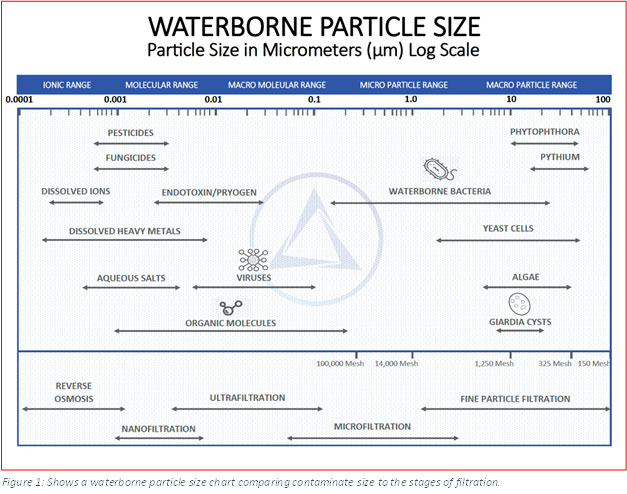

Filtration is the mechanical process of removing contaminants from water. Filtration consists of some filter medium, usually a screen or material with small openings, which then has a flow sent through it. The medium will allow water and small enough particles to pass through but will stop larger particles from passing through. The filtration process is usually broken up into five stages. Each stage helps to target a specific size range of contaminants, this allows the customization of the filtration process based on the water quality. By understanding the filtration process and the different filter materials available, growers can control what is in their water.

FILTRATION HAPPENS IN STAGES

The quality of the water present determines the stages of filtration needed for clean water to be supplied. A single filter is not an efficient universal solution if the quality of the water is especially poor. As previously mentioned, the filtration process is generally broken down into five stages. This helps reduce downtime for cleaning/backwashing cycle as fewer contaminants are filtered in each stage. As the stages progress from fine particle filtration to reverse osmosis, smaller contaminants are filtered out, but more energy is also required to have a continuous flow through the filters due to increased friction.

THE FIVE STAGES OF FILTRATION

Fine Particle Filtration (Pre-Filtration)

- Sometimes considered pre-filtration since it only removes the largest of contaminants including sediment, algae, and some bacteria

- Essential for the longevity of the later filters in the system

Microfiltration

- Functionally the same as fine particle filtration, but targeting smaller contaminants

- Usually secondary filters, used to catch any leaking media from upstream filters

Ultrafiltration

- Filters out pathogenic contamination (viruses and bacteria)

- Includes the sterilization of pathogens using UV light

- Includes absorption through activated carbon filters

Nanofiltration

- Operates on the same principles as RO, but limited to a molecular weight of 100-200 Daltons

- Filters salts, heavy metals, and pesticides/fungicides

Reverse Osmosis

- Filters consist of multiple membrane layers that water is forced through

- Filters the same particulate as nanofiltration with the inclusion of some dissolved ions

- Requires a large amount of energy to drive the process

TYPES OF MECHANICAL FILTERS

The five stages of filtration of can be covered using a variety of filters. Listed below are the most common types of filters used to improve water quality.

Media

- Commonly used to remove solids as a first step in the filtration process

- Suited for filtering out organic and inorganic contaminants, though they work exceptionally well with water heavy with organic matter

- Sand media filters can entrap and hold large quantities of contaminants because of their high-volume nature

- Consists of two or more single tanks connected in parallel with common manifolds serving the inlet and outlet

Screen

- Usually used to filter out inorganic contaminants (silt, sand, scale)

- Typical location would be downstream media filters to catch leaking contaminants

- Can remove small to moderate amounts of organic contaminants at the cost of flow efficiency

- Includes blowdown and wye strainers

- Usually measured in mesh

Disk

- A hybrid between a media tank and a tubular screen

- The crosshatch pattern of grooves on the disks’ surfaces allows water to flow through while retaining solids

- Usually measured in microns

Cartridge

- Highly customizable and easily available to most growers

- Most cartridges contain a paper filter which works just like a screen filter

- They remove organic matter well because the paper texture is rough which helps with the catching of organic matter

- Usually disposable for ease of use

Membrane

- Smallest pore size available

- Compaction of membrane layers determines pore size

- Used in ultrafiltration, nanofiltration, and reverse osmosis

- Requires the largest amount of energy to have a continuous flow